Some Known Questions About Motorcycle Parts New Zealand Specialists.

Table of ContentsMotorcycle Parts New Zealand Specialists for DummiesThe 3-Minute Rule for Motorcycle Parts New Zealand SpecialistsThe Single Strategy To Use For Motorcycle Parts New Zealand SpecialistsThe 3-Minute Rule for Motorcycle Parts New Zealand SpecialistsEverything about Motorcycle Parts New Zealand SpecialistsThe 5-Minute Rule for Motorcycle Parts New Zealand SpecialistsOur Motorcycle Parts New Zealand Specialists IdeasThe Main Principles Of Motorcycle Parts New Zealand Specialists

So, get to out to among our professionals today.CNC machining innovation is rapidly ending up being the centerpiece of lots of different manufacturing processes around the globe as a straight outcome of its lots of advantages over other approaches. Furthermore, the markets that manufacture motorbikes have actually hopped on board with this trend. One of the most innovative firms are now developing their engine components and wheels using machining techniques initially developed for motorcycle parts.

On the other hand, the results of market are the primary emphasis of this write-up. Allow's get directly right into it. You may be asking yourself why we utilize. It is not hard to fathom the variables that resulted in this result. Now that we have your attention let us discuss the rationale behind this modern advancement in the motorbike manufacturing sector.

Getting My Motorcycle Parts New Zealand Specialists To Work

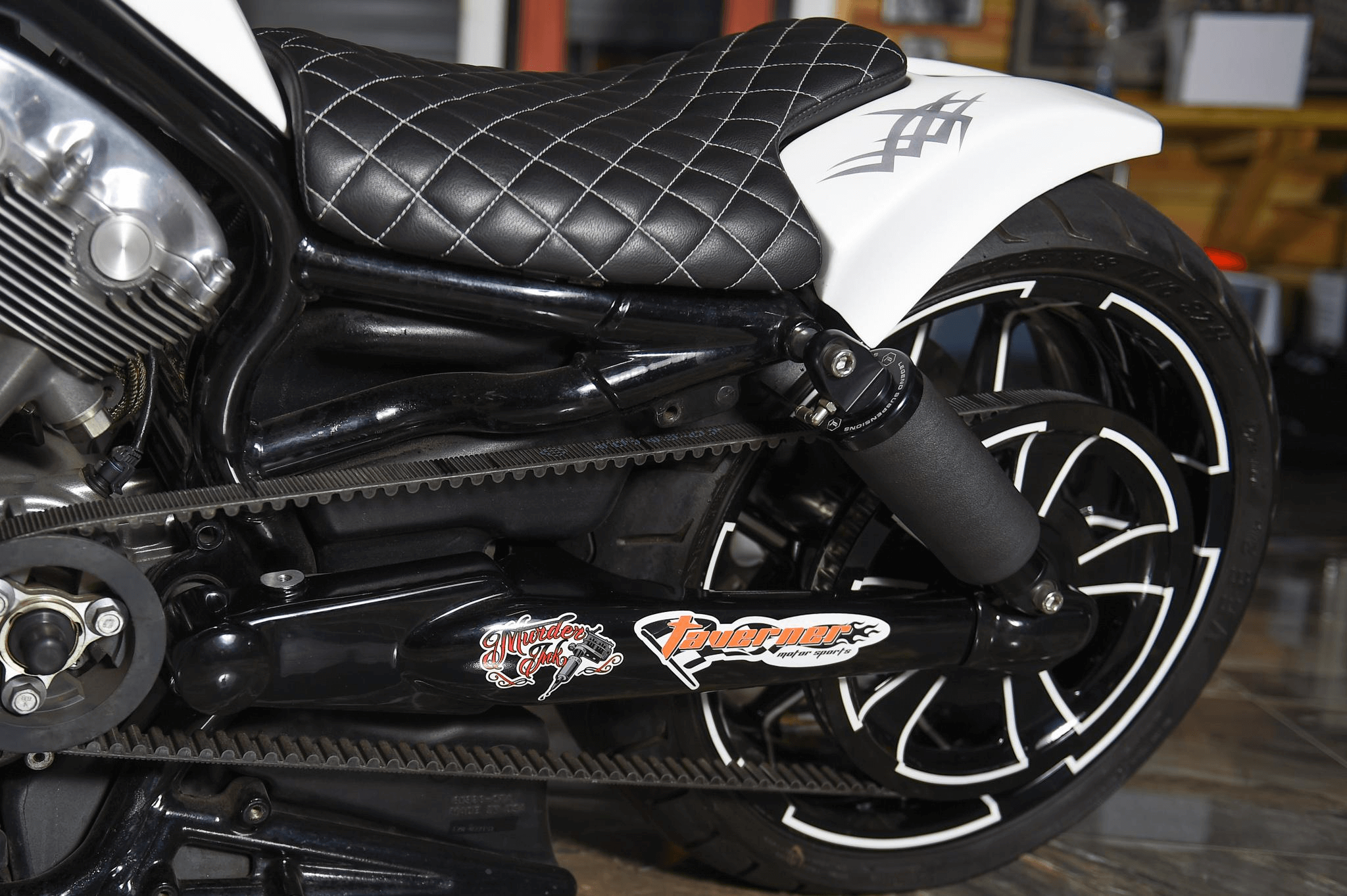

Furthermore, you have total control over the look of the parts, also down to the min information. Occasionally, motorcyclists may determine to beautify their trip by setting up aftermarket elements or modifying the bike's transformation. Once more, computer system mathematical control (CNC) machining is one of the most sensible technique. Upgrades might be of any kind of kind and style you desire.

Things about Motorcycle Parts New Zealand Specialists

CNC machining might be utilized to make nearly all of a motorbike's metal and plastic components. To proceed, we'll discuss several machined components for bikes.

When personalizing the wheels, the disks are where the focus ought to be. The majority of them are constructed of light weight aluminum. Light weight aluminum alloys are popular for the impressive machining capacities that they have. Milling treatments are used to acquire the wanted level of wheel modification. An additional element of the bike that may be customized is the tires.

Some Known Details About Motorcycle Parts New Zealand Specialists

When it involves an automobile (or a motorbike), the most crucial component is the engine. A number of individuals mention it as the "heart" of the automobile. On the various other hand, the camshaft, the cylinder head, and the pistons have a tendency to be elaborate and call for styles with a high level of accuracy.

Usage just top notch items, however, because these lights are crucial for the safety of motorcyclists and other motorists or people on the road, especially at night. Bike headlights have 3 main components: the bulb, or light source, the lens, and the housing.

Milling processes with a perfect finish would certainly result in the lenses having a reflective high quality that resembles that of a mirror. The cover, on the other hand, is not composed of vulnerable materials; instead, it is created out of hard polymers that can be machined right into more complex patterns.

The Ultimate Guide To Motorcycle Parts New Zealand Specialists

They typically Extra resources have fancy geometries with a riches of min information. Motorbike manufacturers usually cast these components, but just for the production of bespoke parts. CNC machining is the technique of choice when producing special pieces. Machining on five axes in today's world is the means by which any layout shape may be realized.

The success of the process is contingent on the mill cutters' capacity to calculate subtle and challenging angles accurately. Select Runsom for your personalized motorbike components! We have the ability to make challenging and trendy components making your bike matchless. The majority of are crafted from light weight aluminum or steel alloys, each of which has its usages and benefits.

Here are a couple of examples of steels commonly used in bike element machining. Light weight aluminum is the key product made use of by business concentrating on producing custom bike components to create the majority of these parts. In the past, we would build our engines out of actors iron. On the other hand, aluminum is swiftly ending up being the product of option, partly as a result of the reality that it is extra light-weight.

Zinc describes an additional steel that is very light in weight and has great machining qualities because of its high mechanical toughness. This material may be formed into nearly any type of form and maintains its measurements well. Also mission-critical elements that require a high level of precision may take advantage of their usage.

Motorcycle Parts New Zealand Specialists Things To Know Before You Get This

Another metal that sees heavy use in the manufacturing of CNC-customized components is magnesium. It is among the lightest metals that are now obtainable and has superb you can try here machinability features and toughness compatible with its reduced weight. Among the downsides of magnesium is that its dust may easily ignite.

Due to its exceptional machinability and weldability, stainless steel is an alloy that is especially well-suited for CNC processes. In addition to this, they have wonderful deterioration resistance and a high aesthetic charm. Their most usual usage in creating different motorbike components is fasteners, such as screws and bolts. Their low susceptibility to oxidation and rust makes them perfect for this use.

Unknown Facts About Motorcycle Parts New Zealand Specialists

It appears that CNC transforming and crushing are the foundational processes. Nonetheless, alternate techniques exist, such as exploration. Allow's explore a number of these machining strategies extensive. The CNC turning method is considered a subtractive manufacturing method. Additionally, it requires maintaining bars of material, frequently plastic or steel, in placement and afterwards twisting a reducing tool to remove areas of the material as the material is transformed.

These techniques are just as crucial and create parts with high accuracy and regular high quality. They are respectively: grinding, laser cutting, and exploration. The term "surface finish" describes post-processes after the first machining stage. Motorcycle Parts New Zealand Specialists. The procedures aid enhance the overall top quality of the machined motorbike parts. Below are the short intro, advantages and disadvantages of 5 surface area treatment methods.

Motorcycle Parts New Zealand Specialists - Truths